Which way for whey? By Brian Klepacki, MS, CISSN, CSCS

Are you sick and tired of trying to navigate through the world of choosing the ‘right’ whey protein for your needs? Just like for you, protein supplementation is a critical part of my daily diet. And if it isn’t a part of yours, why the heck not?? There is more than enough research on  the importance of (whey) protein and all the benefits it brings with it. But now, thanks to those sneaky business and marketing guys (and gals), the process of finding that ‘perfect’ protein is even more challenging than ever. You are probably thinking that the protein you are religiously buying is the best. Maybe it is or maybe it isn’t. I’m not here to promote any company or to criticize what you are doing, I’m simply writing this as an informational tool for you to use when choosing your next batch of protein. As Jose always told me in grad school, “if it helps or has a neutral effect, then do it.”

the importance of (whey) protein and all the benefits it brings with it. But now, thanks to those sneaky business and marketing guys (and gals), the process of finding that ‘perfect’ protein is even more challenging than ever. You are probably thinking that the protein you are religiously buying is the best. Maybe it is or maybe it isn’t. I’m not here to promote any company or to criticize what you are doing, I’m simply writing this as an informational tool for you to use when choosing your next batch of protein. As Jose always told me in grad school, “if it helps or has a neutral effect, then do it.”

Pick up your protein tub and read off some of the major bullet points of their bold claims. You might notice a few words like hydrolyzed or cross-flow microfiltration or reverse osmosis. We are seeing these words plastered all over the protein world these days and at first, we might say things like, “oh, that sounds really cool,” or “nice, this must be healthy stuff,” and that’s exactly what the companies want us to think, but the truth is, most of the general population either doesn’t care or has no clue what this scientific jargon really means. Shouldn’t we know what this means since we want the best for our body? Does it really matter to us and our muscles? So why did the supplement world have to go all nerdy on us in the past few years and confuse everyone even more? Don’t they know that we only care about how many friends we have on Facebook or how big our calves are? Maybe there is significance to the way we get our whey.

In the whey protein processing world, there are two main methods of protein filtration. Before we dive right into defining these different processes, we need a quick 101 on how whey protein powder is made. In a nutshell, whey is the one of two major proteins found in cow’s milk. The other protein is casein [1]. Upon the separation of the multitude of constituted parts of milk to make cheese, whey protein is the byproduct of this process. From this point, the whey (liquid form) is then pasteurized and dried into powder for our use. Now coming back to this discussion, the process of which the whey is derived varies and that’s what I’m hoping to help you better understand. Let’s put on our learning caps and get down to what these terms really mean.

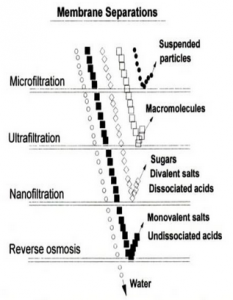

One of the most widely used methods is membrane filtration, aka micro and/or ultra [1]. All whey mediums have been processed through a form of membrane filtration one way or another. Due to the complexity of the many different types of micro and ultra filtration, know that these two types, regardless of the method, are fundamentally similar. Membrane filtration is basically a filter with microscopic holes to filter out any impurities thus resulting in a finer grade of product. The amount of filtering depends on the type of process being used by the factory or farm. One of the main techniques in whey processing is cross flow microfiltration. By definition, this particular process gets its name because the majority of the feed flows across the surface of the filter, rather than into a dead end filter [3]. (Think of a funnel vs. a slip and slide that has holes in it). It’s obvious that more sediment and particles will be picked up in a shorter amount of time through the cross flow than a standard dead end method.

So what’s the end result of the cross-flow filtration? That’s still a tough question to give a definite answer to because there are many external factors that will greatly impact the end result of the product. Factors like thickness of the medium and the filter, the rate of flow and temperature of the medium. All of these do have an impact on the process, just like weather affects aerodynamics etc. You need to ask  yourself the basic question of what is my intention and purpose is for taking a whey protein supplementation. Going back to the marketing standpoint, you will see adjectives like dynamic, ultra, mega ultra, triple maximal deluxe ultra and others like it just to get your attention. This is a way that Company X claims that their protein is the purest protein on the planet. Just keep in mind that even though a company might have the most elite and elaborate filtration system known to man, they could still add cheap and dangerous fillers to negate the cost of their expensive technique [2]. That’s neither here nor there.

yourself the basic question of what is my intention and purpose is for taking a whey protein supplementation. Going back to the marketing standpoint, you will see adjectives like dynamic, ultra, mega ultra, triple maximal deluxe ultra and others like it just to get your attention. This is a way that Company X claims that their protein is the purest protein on the planet. Just keep in mind that even though a company might have the most elite and elaborate filtration system known to man, they could still add cheap and dangerous fillers to negate the cost of their expensive technique [2]. That’s neither here nor there.

So a general rule of thumb in the degree of filtration is “nano > ultra > micro”. The finer the filtration, the more pure and decontaminated the protein becomes [1,3]. This might sound like a good thing but it could pose a potential problem when looking at protein at its biological platform. Certain substances (i.e. phospholipids and immunoglobulins) and other peptides that have been shown to have an influence on the integrity and nutritional makeup of whey will ultimately be extracted and eliminated from the final protein concentration [3]. Furthermore, this sets up the difference between concentrate and isolate. Not to confuse you anymore or open up a whole new discussion, go back to that question of what is your purpose of consuming whey and why you buy what you choose. It’s important to know which way whey is processed during membrane filtration in order to best suit your needs.

The second most commonly used method is called ion exchange. Essentially ion exchange is defined as an exchange of ions between two solutions. This method has a slightly different approach to processing whey. Unlike membrane filtration, ion exchange relies on chemicals to do the work. In the case of whey, this allows certain substances in the whey liquid to be pulled out according to their electrical charge. These substances or contaminants are extracted by two little guys known as hydrochloric acid and sodium hydroxide [6]. (Remember the whole ion/cation/anion talk in chemistry class?) This might seem like a more effective and precise method but know that certain protein peptides are very fragile to pH changes and even the slightest electrical change can cause the bioactivity of the protein to be reduced thus resulting in a denatured or inadequate protein. Maintaining the natural state of the protein is important for various reasons but research hasn’t proved that this is essential for your physique or for athletics. In other words, you won’t be able to tell the difference if your protein shake is denatured or not. More research needs to be done to see the long term effects of consuming denatured vs. non-denatured protein supplementation on performance.

The last method that I want to touch on is hydrolyzing. Defined, hydrolyzed whey is whey protein that is processed by treating it with acid conditions and high heat to isolate the protein [3, 5]. This process creates small bonds that link the amino acids together. The purpose of this is to create a faster and easier digesting protein for consumption. You might be saying to yourself, “hydrolyzed, that sounds familiar.” This whey has been around the block a time or two. Hydrolyzed protein powders were popular a while back but then fell off the map because of the awful taste, hefty price tag and no concrete evidence that it was any better than its counterparts. Also, it was more evident that this method denatured the protein to a much greater degree than ion exchange. However, thanks to advancements in technology, companies are finding ways to reinvent this process by keeping the protein’s blueprint untouched yet being able to make it a more pleasing on the palate and bank account [2,3].

So there you have it, a rough break down of a few of the main methods of processing protein to give us whey. Each process has its pros and cons just like everything else. What you do with this information is up to you but what I will ask of you is that you take this new found knowledge and continue to grow it. Never stop learning.

________

Brian Klepacki, MS, CISSN, CSCS

Owner of Optimax Performance Training

brian@optimaxperformance.com

www.Optimaxperformance.com

[1] Bishop, Mathison, and Smith. Dairy Proteins. Wisconsin Center for Dairy Research, Wisconsin Milk Marketing Board. http://future.aae.wisc.edu/publications/dairyproteins.pdf 2001.

[2] Howie, M. Reverse osmosis, ultrafiltration decrease transportation costs. Feedstuffs. 1999; 71: 33 (10)

[3] Saboya, L.V. and Maubois, J.L. Current developments of microfiltration technology in the dairy industry. Lait. 2000; 80: 541–553

[4] Bacher and Konigsfeldt, 2000Bacher, T. and Konigsfeldt, P. WPI by microfiltration of skim milk. Eur. Dairy Mag. 2000; 5: 14–16

[5] http://www.adpi.org/DairyProducts/Whey

[6] Schmidt, Ronald H.Packard, Vernal S. et al. Effect of Processing on Whey Protein Functionality. Journal of Dairy Science, Volume 67 , Issue 11 , 2723 – 2733. 1983